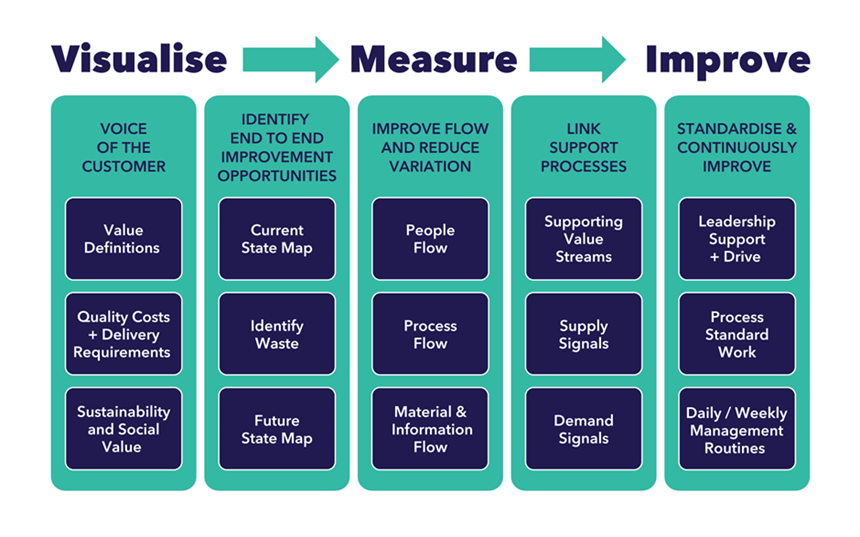

In a sector that spends 7 times more than its annual profit on correcting errors, operational improvement is essential if construction is to thrive in 2022. By implementing a Value Stream end to end focus, you can clearly define opportunities to improve and build a prioritised improvement plan that engages teams to deliver impactful change. So, what does Value Stream mapping look like?

Identify value for your customer

The first step for any successful construction business is to determine the needs and expectations of your customers. From this foundation, you can build a clear set of values for the company to refer back to at any stage of the project.

Getting to know the voice of the customer also helps you to determine the quality costs and delivery requirements. By understanding their needs, you can provide them with the best possible service in the most efficient way, helping to reduce wasted effort and resources.

Identify end-to-end improvement opportunities

BBI help construction businesses to undergo an effective end-to-end analysis of all their processes, internal and external. This process optimisation is crucial as it helps businesses to comprehend their current state and identify areas where money and resources are being wasted, and value is being lost. Only when the current state is known, can an improved future state be planned.

Improving flow and reducing variation

By streamlining all your processes and introducing standardised ways of working, the business can drastically improve the flow of its people and processes. BBI help companies to develop manufacturing systems which are simple, clear, streamlined and optimised which can be spread across the business.

With everyone singing from the same hymn sheet, businesses can be much more hopeful of a swift and profitable programme delivery.

Establishing link support processes

At this stage, we assist businesses in setting up frameworks that support value streams. That means improving interfaces across the supply chain and functions to ensure the swift delivery of quality products.

It also entails establish clear supply and demand signals so that the right product is delivered in the right way, at the right time, every time.

Standardise and continuously improve your processes

Once you’ve established the best practice, make it the common practice. Engage the workforce to determine which parts of the manufacturing systems are working and which need further improvement.

As experts of the construction sector, BBI can help businesses to visually map Value Streams to identify areas where opportunities for improvement are being missed. Then, we can help to implement leadership support systems and regular management routines to secure a steady flow of quality running from the construction site to the customer.

Improving manufacturing systems across the UK construction sector

BBI Services’ team of industry experts will work with you to optimise your processes, improve your output quality, and implement a Right-First-Time mindset across the business. For more information, please contact us online or call 01608 664589.